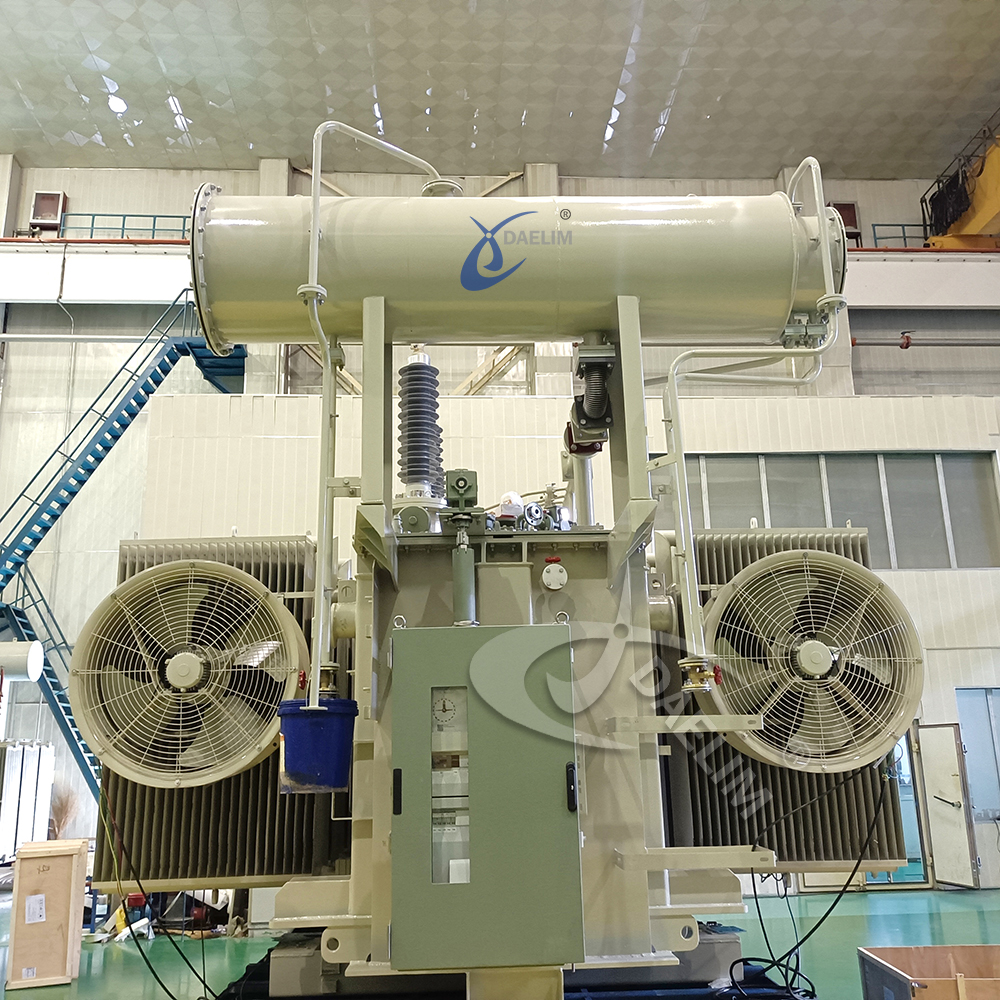

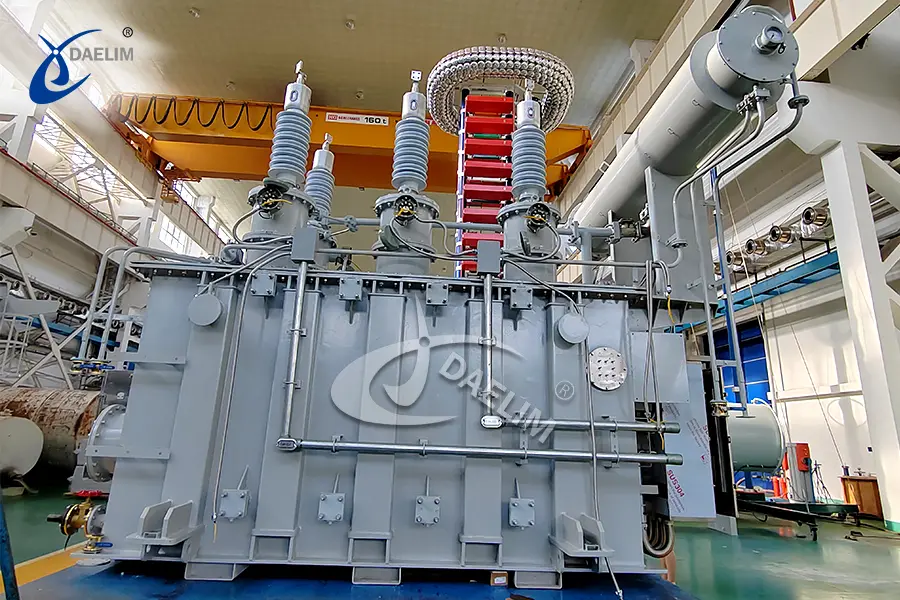

35MVA 115kV 3 Phase Power Transformer

- Primary Voltage Ratings: 115kV

- Secondary Voltage Ratings: 13.8kV

- H.V. TAP RANGE: 115kV ± 8 × 0.625%

- CONNECTION TYPE: YNd1

- TYPE: On load tap changer power transformer

- BIL: 450/110kV

- Standards: IEEE

- Application: New Energy

- Power Rating: 20,500/27,200/35,000kVA

- Cooling Method: ONAN/ONAF1/ONAF2

The 35MVA 115kV 3 Phase Power Transformer, manufactured in December 2024, is a state-of-the-art electrical device designed to serve critical applications in renewable energy projects. Delivered to a key client in California, USA, this transformer is a key component in advancing clean energy solutions. It is built to meet the highest standards of performance, reliability, and energy efficiency, ensuring optimal operation in both conventional and renewable energy systems.

Quote Now

Key Features & Performance

- Compliance with IEEE C57.12.00: The 35MVA 115kV transformer adheres to international industry standards, ensuring superior quality and performance.

- Low Loss and High Efficiency: Designed with low core and copper losses, this transformer significantly reduces energy consumption, contributing to sustainability and cost-effectiveness.

- Reduced Partial Discharge and Noise: Engineered for low partial discharge (PD) and noise emissions, it ensures a quieter operation while maintaining long-term stability.

- Short-Circuit Resistance: The transformer is designed to withstand high fault currents, improving the overall safety and durability of the system.

- Leakage-Free Design: With robust construction, this transformer is designed to prevent oil leakage, enhancing environmental safety and system reliability.

35MVA 115kV Power Transformer

Advanced Materials and Construction

- Core and Coil Materials: The transformer’s core is constructed with high-grade, high-permeability silicon steel, featuring an advanced step-lap jointing technique at 45° for optimal magnetic flux. The surface is coated with a special anti-corrosive layer, reducing no-load losses and minimizing noise levels.

- Low-Noise and Enhanced Durability: The coil and core assembly includes proprietary design features like core bracing and the use of transposed conductor wires, ensuring minimal noise generation and long-term stability.

On-Load Tap Changer (OLTC)

- The 35MVA transformer is equipped with an On-Load Tap Changer (OLTC) on the high-voltage side, allowing for voltage regulation in the range of 115kV ± 8 × 0.625%.

- The OLTC includes a conservator, oil level indicator, Buchholz relay, and self-regenerating breather, all contributing to the transformer's safe and stable operation.

Protection and Safety Features

- Gas and Differential Protection: The transformer is equipped with gas protection and differential protection relays to ensure safe operation and early fault detection.

- Relay Monitoring: The unit features both internal and external relays that trigger alarms and initiate automatic tripping if any abnormal gas or oil fluctuations are detected.

- Oil Level Monitoring: The oil level indicators monitor the status of the oil tank, with alarms triggered if the oil level falls outside the specified range, ensuring optimal oil maintenance.

Pressure Relief Valve

In the event of rapid internal gas buildup due to fault conditions, the transformer is equipped with a pressure relief valve. This system discharges excess gas, preventing excessive pressure and allowing the control room to take immediate action by triggering an automatic trip.

Temperature Monitoring

- Oil and Winding Temperature Indicators: The transformer is equipped with sensors to monitor oil and winding temperatures. If temperatures exceed 95°C, an alarm signal is sent to the remote monitoring room. If the temperature exceeds 105°C, the transformer will automatically trip to prevent overheating and potential damage.

Cooling System

The transformer features a two-stage cooling system:

- Stage 1: The first cooling fan activates when the winding temperature exceeds 75°C.

- Stage 2: A second fan activates when the temperature reaches 80°C.

When the temperature drops below 75°C, the fans automatically turn off, ensuring efficient cooling and minimizing energy consumption.

Self-Regenerating Breather

Both the transformer’s main body and tap changer conservator are equipped with a self-regenerating breather (Qualitrol brand). The breather uses a built-in desiccant (silica gel) that absorbs moisture and regenerates through heating, preventing moisture and air from entering the transformer. This ensures the insulation remains dry, supporting the transformer's long-term operational stability.

Applications

- Renewable Energy Projects (Solar, Wind, etc.)

- Industrial Power Distribution

- Grid Stabilization

- High-Reliability Power Systems

Conclusion

The 35MVA 115kV Three-Phase Power Transformer is a cutting-edge, high-performance solution for modern power distribution systems, particularly in renewable energy sectors. With advanced materials, superior safety features, and energy-saving design, it offers high efficiency, reliability, and long service life. This product exemplifies Daelim Transformer’s commitment to delivering innovative, quality solutions to meet the demands of a sustainable energy future.

Ready to Power the Future of Energy?

Contact us today to learn more about how the 35MVA 115kV Three-Phase Power Transformer can enhance your renewable energy projects and ensure reliable, efficient power distribution.

Related Products

Related Article