Step Up Transformer VS Step Down Transformer

Transformers help transmit alternating current (AC) from one circuit to another while maintaining the frequency and, in most cases, have a different voltage. Although it is economically required to transmit energy at high voltage, it must be used at low voltage to prevent harm. There is a rise in transmission voltage and a decrease in usage, and it is only viable when there is a step up transformer and a step down transformer.

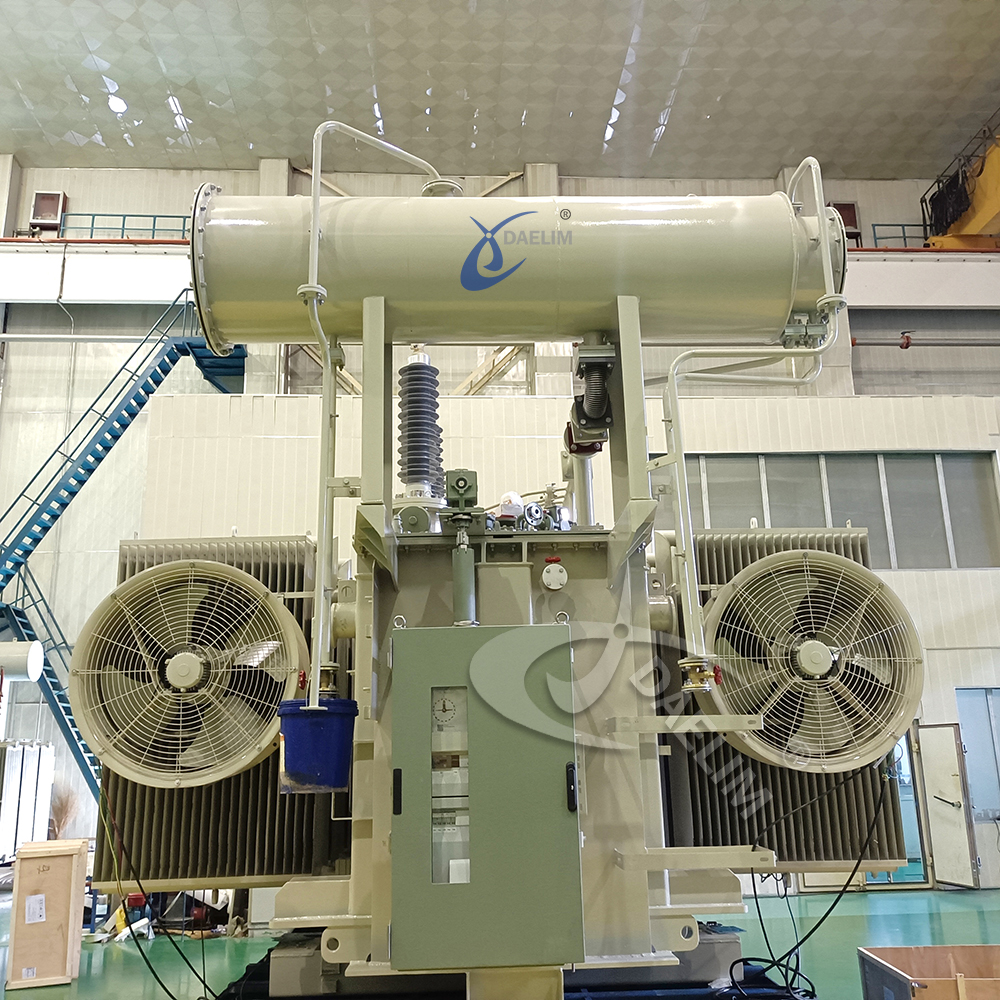

Daelim is ANSI/IEEE, UL transformer manufacturer who has been cooperating with many popular brands such as AMAZON, EATON, and SOLOMON brands in the US. Daelim production of step up and step down transformers meet various international standards. Such as: IEEE/ANSI, CSA, AS/NZS, GOST, EN, etc.

Contact Daelim TransformerMy first question is what type of regulation do these electrical transformers do? Do they increase voltage or current or do they decrease it? Answer of this lies in the type of transformer, whether it is a step up or step down transformer.

So, the second question arises: what are these step up or step down transformers and how are they different? We will explain this in our step up transformer vs step down transformer guide.

Step-Up Transformer vs Step-Down Transformer: Key Differences

Basic Definition

If we try to define these transformers, then their names step up and step down transformers are sufficient. Step up transformers are those transformers that step up the electricity provided to them while step down transformers are those transformers that step down the electricity provided to them.

What does this stepping up and stepping down of electricity really mean in transformers regulating the electricity.

Voltage and Current Behavior

When we say that step up and step down transformers step up and step down the electricity provided to them respectively. Then they are basically regulating the voltage and current provided to them.

Step up transformers step up the electricity by increasing the voltage and reducing the electric current provided to them. Opposite to this step down transformers step down the electricity by reducing the voltage and increasing the current provided to them.

Primary Functionality

Primary function of the step up transformer is to step up the provided voltage to the level that it can be easily transmitted from the electrical grid station to the local consumers installation. This increase in voltage is very important for transmitting electricity with small losses but this increased voltage cannot be used by consumers installations.

This is where step down transformers came in. Step down transformers are designed and developed to reduce the initially increased voltage to the level that it is safe for consumer appliances.

There is one similarity in both types of electric transformers here. Both are designed and developed to reduce the fluctuation in their output, even if there is any sudden fluctuation in supply or demand.

Key Components

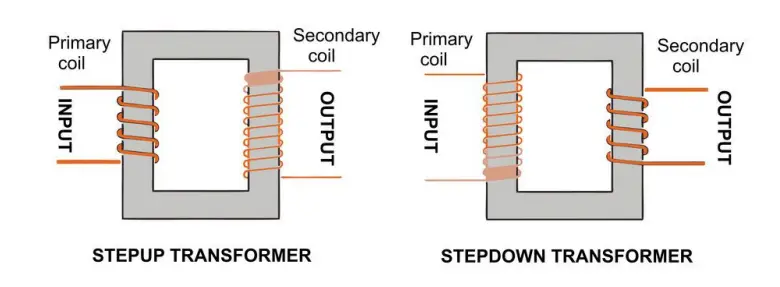

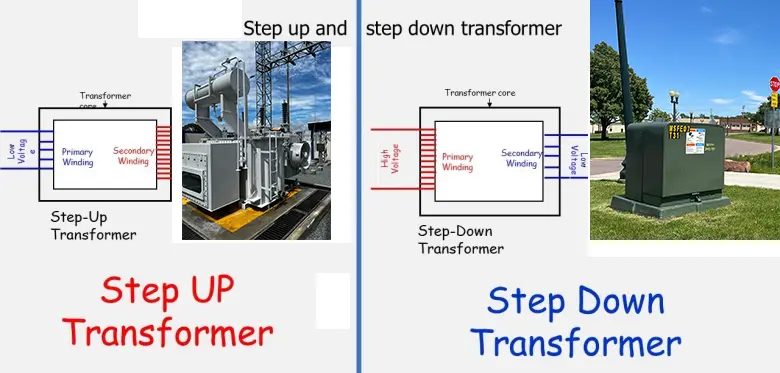

Working principle of both transformers is the same as they both work to regulate electricity. Due to this almost all of the transformer parts are the same for both transformers. There is only a small technical difference in the winding and core of the step up and step down transformer.

As a step up transformer has to increase the voltage using the principle of electromagnetic flux and induction. So the number of turns in the secondary winding of the step up transformer are more than the number of turns in its primary winding.

Similarly a step down transformer has to reduce the voltage using the principle of electromagnetic flux and induction. So the number of turns in the secondary winding of the step down transformer are always less than the number of turns in its primary winding. This is clearly presented in the step up transformer vs step down transformer wiring diagram shown below.

More resource: How Transformer Components Function Together to Control & Deliver Electricity?

Step Up Transformer VS Step Down Transformer price

Step-up transformers are generally more expensive than step-down transformers due to their design requirements. Such requirements include higher insulation levels and robust construction for handling high voltages. However the exact price difference depends on factors like size, capacity, and manufacturer.

Efficiency and Power Loss

Electrical power transformers are very efficient equipment but if we compare the efficiency of step up and step down transformers, step up transformers are more efficient. Reason why step up transformers are more efficient compared to step down transformers is that step up transformers reduce current and lower current for transmission with increased voltage means lower losses in the process.

How this works is that each material has its own resistance against current flow. Copper, which is the most used material for transformer winding, is an excellent conductor of electric current but still has some resistance.

So in Step up transformers, current is reduced in the secondary coil of winding resulting in less current losses in the winding. Opposite to that, current is increased in step down transformers and so the resistance due to it which can be observed in the form of heat.

This is only one aspect and the efficiency and power losses depend on a lot of other factors like core material and quality of design and manufacturing of all other transformer parts.

Applications Comparison

Due to such a wide difference in the output of each of the transformers, the field of application of each transformer is very different.

Due to such a wide difference in the output of each of the transformers, the field of application of each transformer is very different.

In the power generation sector, step up transformers are used to facilitate the efficient transmission of electricity over an extensive network. The step down transformers have no application in power generation sectors as they are not designed and developed to facilitate the transmission of electricity.

In industrial installations, step up transformers are used to step up the voltage to meet the voltage requirements of specific machines. This specific application of step up transformers is neither versatile nor much common as they are only applied to a number of heavy industries.

In industrial and domestic applications, step down transformers are very widely used to reduce the incoming voltage to the level that it is safe for use in industries and for domestic appliances.

Step down transformers are also widely used as an integral part of machines and appliances used in small industries and homes like phone battery charges. Step up and step down transformer diagrams are shown below.

In the renewable energy sector, step up transformers are widely used whenever there is a large installation to supply electricity to national grid stations. As all machines and types of renewable energy like solar parks or wind turbines produce electricity at much lower voltage than the national grid standard.

So Step up transformers are used to initially increase the generated voltage to the level of national grid stations and then to for transmission at long distances. In such large scale installations, a step down transformer is always required to step down the voltage for consumers.

Choosing Between a Step-Up and Step-Down Transformer

The choice between the two depends on voltage requirements, transmission distance, and load conditions. For high-voltage applications, a step-up transformer is ideal, whereas step-down transformers are suitable for systems requiring lower, safe voltages.

Conclusion

Step up transformer vs step down transformer are vital components of modern electrical systems with each serving distinct purposes. Step up transformers work to increase voltage for efficient long distance power transmission.

Step down transformers work to reduce voltage to safe levels for end user applications. Understanding their functionality, applications, and efficiency helps ensure the optimal selection and utilization of these indispensable devices in power systems.

Follow Up

At Daelim Transformer, we supply both step-up and step-down transformers to customers across the Americas, Europe, Australia, and other regions. We have hundreds of transformers in stock at our facilities in Houston and our factories in China. Start your urgent project without delay.

We specialize in meeting the urgent needs of industries such as crypto mining, data centers, and manufacturing. Additionally, we offer comprehensive transformer services, including repair, maintenance, installation, testing, and field support.

Contact us, and our team will guide you through the process.

Related Products

Related Article

2600 kVA Pad Mounted Transformer For Crypto Mine In Kansas

This morning, I received the on-site photos of the pad-mounted transformers from the customer, and I was overwhelmed with excitement and joy. These pad-mounted transformers are installed at a 20MW crypto mining site in Kansas, USA. A total of 5 sets of 2600 kVA pad-mounted transformers, all UL-listed, are being deployed at this site. Currently, 3 sets have already been installed onsite and are scheduled to be powered on imminently.

Pad Mounted Transformer For High Voltage Substation

FWS commissioned Daelim Transformer to design and manufacture a new high voltage substation for the Richardson International Canola Crush facility expansion in Yorkton, SK. The project required two specially designed top-in pad-mounted transformers, one 2 MVA and one 5 MVA. Unable to meet the delivery deadline, local North American suppliers led FWS to choose Daelim Transformer for their capacity and quality. The transformers were successfully produced and delivered within 16 weeks and are now operating safely.

20MVA Power Transformer for the United States

This project involves the development of a 20 MVA three-phase power transformer tailored for the United States market. The primary voltage is 24.94kV, and the secondary voltage is 4.16kV, indicating it functions as a step-down transformer. The design and production fully comply with IEEE C57.12.00 standards and have passed third-party UL team testing. All accessories also adhere to IEEE standards. FR3 vegetable oil serves as the insulating liquid for the transformers.

How Long Does It Take To Repair A Transformer?

The time required to repair a transformer depends on factors such as the extent of damage, part availability, accessibility, and the expertise of the repair team. Minor issues like short circuits or blown fuses can often be fixed within an hour, while more complex repairs, such as replacing bushings or pumps, may take several hours or a day. Major faults, like oil leaks or winding damage, could take several days to weeks to fully repair. Timely repairs are also influenced by the accessibility of the site and the experience of the repair team.

Conservator Transformers and Their Role in Power System Reliability

Conservator transformers play a critical role in enhancing power system reliability by maintaining optimal oil levels, preventing overheating, and protecting against contamination. The conservator tank stores extra oil, allowing for temperature-related expansion and contraction. It also keeps oil clean by shielding it from air, dust, and moisture. Types of conservators include corrugated, capsule, and diaphragm, each offering unique benefits. Daelim’s conservator transformers, designed to meet international standards, ensure long-lasting efficiency, safety, and reduced maintenance in power systems worldwide.

Transformer Solutions for Electricity Generation

Daelim Transformer offers tailored solutions for power generation, supporting efficient electricity transmission globally. With expertise in Europe, America, and Australia, Daelim provides high-performance transformers designed for renewable energy integration, large-scale transmission, and remote off-grid areas. Key solutions include step-up transformers, ecodesign transformers, and auxiliary transformers, ensuring minimal energy loss, sustainability, and reliability. Daelim’s transformers meet global standards, offering scalable and customizable options for diverse power generation needs. With proven expertise and global support, Daelim ensures safe, efficient, and reliable power systems for various energy projects worldwide.