Transformer Design: Step by Step Guide for Safety and Reliable Power Flow

Transformers are the most important appliances through which electricity reaches any place, either a small house or a giant factory. They transform the voltage level, and everything works according to that because each transformer has some usage.

Let us now proceed to the design of transformers and the engineering involved in doing so.

Contact Daelim TransformerTransformers are the most important appliances through which electricity reaches any place, either a small house or a giant factory. They transform the voltage level, and everything works according to that because each transformer has some usage.

Let us now proceed to the design of transformers and the engineering involved in doing so.

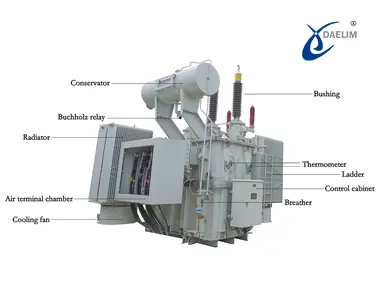

Daelim Transformer's three-phase substation transformers are designed for high voltages up to 44 kV and ratings of up to 20 MVA, compliant with global standards such as ANSI/IEEE C57, CSA C88, IEC 60076, and AS. These transformers are equipped with monitoring system accessories and feature components from internationally renowned brands like ABB, Copper, and Qualitrol.

Daelim Transformer offers a complete line of oil-immersed transformers that meet current applicable standards, including IEC, IEEE, ANSI, CSA, NEMA, AS/NZS, and GOST. Our high-voltage power transformers are available for voltages up to 230 kV and ratings up to 300 MVA. We have successfully supplied hundreds of high-voltage power transformers across America.

At our facility in Houston, we have hundreds of transformers in stock, including pad-mounted transformers ranging from 300 kVA to 3000 kVA, with voltage levels of 12.47, 13.2, 13.8, 24.94, and 34.5 kV. We also offer single-phase transformers with capacities from 50 to 175 kVA. There's no need to wait—immediate shipment is available!

Project Background

Perhaps the most daunting challenge in designing a transformer is extreme accuracy in computation and testing. To help streamline this, you can use Transformer Design Calculation Excel.

Perhaps the most daunting challenge in designing a transformer is extreme accuracy in computation and testing. To help streamline this, you can use Transformer Design Calculation Excel.

The calculations spreadsheet helps you determine the MV/LV transformer rating, the calculation of the overcurrent protection device on the transformer’s low voltage side, and the prospective short circuit current faster. This also includes the calculations for natural ventilation openings needed for the ventilation room.

Project Objectives

Before starting any work, ask yourself questions like: "What is the purpose of this transformer?" and "What are the performance requirements?" These objectives act as a roadmap for the whole project.

Relevant Standards

Every industry follows some standards. These ensure everything is safe and reliable. The engineers check industry standards and regulations that the transformer has to be designed according to the official guidelines of the following:

- IEEE Standards - A main standard in the United States but internationally recognized and accepted, particularly on issues that have to do with telecommunication, power, and electronics.

More resource: Ultimate Guide To IEEE C57 Standard

- IEC Standards (International Electrotechnical Commission) - Developed worldwide and primarily used in Europe, Asia, Africa, and other parts of the world for standards in electrical, electronic, and related technologies.

More resource: The Ultimate Guide To IEC 60076 Standard

- ANSI Standards (American National Standards Institute) - Primarily used in the United States to standardize products and services across various industries.

- Environmental and Safety Standards:

-

- EPA (Environmental Protection Agency) - Environmental Protection Agency, environmental standards for the United States.

-

- OSHA (Occupational Safety and Health Administration) - Occupational Safety and Health Administration. Regulations on workplace safety and health in the United States.

-

- RoHS (Restriction of Hazardous Substances) - This came from the European Union, restricts hazardous materials in electrical and electronic equipment. The standard is somewhat similar around the world.

- National Electric Code (NEC) - Electrical safety standards specific to the United States and covered by the National Fire Protection Association (NFPA).

- CSA Standards (Canadian Standards Association) - National standards used widely across Canada, covering electrical, safety, and environmental sectors.

More resource:

Pad Mounted Transformer CSA C227.4 National Standard of Canada

CSA C88 Standard For Power Transformers

CSA C802 For Minimum Efficiency Values For Power Transformers

CSA C227.3 For Single Phase Pad Mounted Distribution Transformer

Three Phase Live Front Pad Mounted Transformers Under CSA C227.5

- AS Standards (Australian Standards) - These are standards widely accepted in Australia for safety purposes, mainly building and construction industries.

- NZS Standards (New Zealand Standards) - Standards specific to the needs of New Zealand, covering industries from electrical to environmental and public safety.

- GOST Standards (Russia and the former Soviet Union) - Historic standards adopted in Russia and other formerly Soviet Union countries containing technical and industrial specifications applied to all spheres.

Requirement Analysis

The specific needs of the transformer have to be studied. Knowing the right transformer design calculations helps engineers make the correct decisions during the design phase.

- Load Characteristics - This refers to the type of load the transformer will be carrying. Some loads take so much power in a very short time, while others remain constant. These changes must be determined to determine if the transformer can support them.

- Voltage Ratings - The main voltage ratings of a transformer are the input voltage, which it receives, and the output voltage that it delivers. The engineers determine the right voltages by viewing the needs of the place or system it is built for.

- Frequency Requirements - The frequency differs slightly in other places. For example, electricity is 60 Hz in America, but in other regions, it is 50 Hz. If the proper frequency is provided, a transformer will not have problems.

Preliminary Design

They are free to make front-end design decisions that should help indicate how to be shaped and performed in the transformer.

- Type Selection: Transformers come in different stock of transformers, including oil-immersed, where parts are submerged into oil to cool them, and dry type, where air cools them. The right type needs to be chosen depending on the location and purposes.

- Basic Parameter Setting: Engineers set basic parameters, such as the capacity of how much power it can handle, the efficiency of how well it converts energy without wasting, and losses of how much energy might be lost in operation.

More resource

Transformer Efficiency: The Ultimate FAQs Guide

Core Design

The core is the heart of the transformer. That’s why it’s very important to know this before knowing how to design transformers. Having knowledge about better core design makes the transformer more efficient.

- Material Selection: The quality of the core material decides how the extent to which the transformer serves the purpose. Silicon steel is commonly used because it has withstood magnetic forces.

- Size Calculation: The size and shape of the core are calculated to handle the power required without overheating. Ferrite core transformer calculation plays a part in this for applications where a compact, efficient core is needed.

- Flux Density: This is the intensity of the magnetic field in the core. The designers ensure that it is within limits because the core material can take under working loads.

More resource

The Crucial Role of Iron Cores in Transformer Design and Function

Winding Design

Windings are the coil of wire wrapped around the transformer core. Proper design is very important in getting the required voltage and power output.

Windings are the coil of wire wrapped around the transformer core. Proper design is very important in getting the required voltage and power output.

- Turns Calculation: Engineers calculate the number of turns needed for each winding. More turns correspond to higher voltage levels; fewer turns correspond to lower voltage levels. This is directly proportional to the outcome of a transformer's design.

- Conductor Selection: These are materials through which electricity can pass. Engineers prefer materials such as copper, that have been used widely because they have low resistance hence electricity can pass easily.

- Current Density - It is the amount of current (electricity flowing) in a given unit area of the conductor, which engineers keep within definite safe limits so that the transformer is not overheated, which can cause damage also.

Cooling System Design

Transformers operate at high temperatures and safety can only be achieved by efficient cooling.

Transformers operate at high temperatures and safety can only be achieved by efficient cooling.

- Cooling Method: In natural cooling, natural air cools the transformer. In forced cooling, the transformer is cooled using fans or oil circulation systems.

- Radiator Design: Radiators basically refer to the metallic fins or structures that allow support in the dispersal of heat. Engineers will design radiators and even parts like oil tanks that support transformer safety in its proper working temperature.

Insulation Design

Just like wearing gloves when touching something hot or dealing with electricity, transformers also guard against electrical faults and keep safety intact.

- Insulation Material Selection: Insulation materials protect the components of the transformer from electrical faults. Engineers use dependable and practical materials at the voltage level the transformer is to handle.

- Thickness Calculation: The right thickness for the needed layers of insulations are calculated such that it remains reliable to voltage.

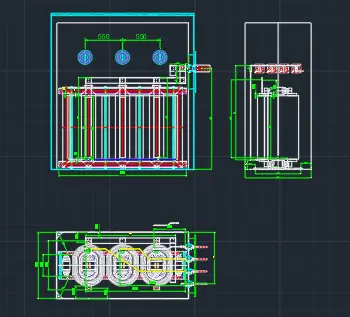

Mechanical Design

The structure of the transformer must be robust enough to support all the components and endure the conditions in its surrounding environment.

- Structural Design: This includes the outer shell and the framework that holds everything together. It ought to be able to hold within it vibrations and exterior forces.

- Transportation and Installation: The engineers also consider how easy it will be to transport and install the transformer. Its planning depends on its weight, size, and other hardware needed to place it in a particular site.

Protection and Safety Design

Engineers add devices and systems to protect the transformer from damage and injury if a person interferes with its passage.

- Protection Devices: Transformers can short-circuit or be under heavy loads. Engineers designed special devices that may cut off or limit the flow of power in case of an emergency.

- Safety Standards: Safety standards are followed to ensure that the transformer is safe, which includes rules that limit exposure to high voltages and avoid fire hazards.

Testing and Validation

Testing is an important procedure that ensures the transformer works exactly as required and is designed before it is used in real life.

- Testing Plan: Engineers design a detailed testing plan that includes insulation testing, which checks for weak spots in the insulation, and load testing, which simulates the transformer's ability to withstand real working conditions.

- Results Analysis: The engineers analyze the results of the problems and possible necessary corrections. Engineers improve or correct as needed to realize better performance.

More resource

How to test a power transformer?

Documentation and Production Preparation

Once a design is finalized, engineers develop documentation that the production team will use.

- Design Documentation: Once the design is finalized, the engineers create detailed documentation so that the production team can complete the construction process accurately and consistently.

- Production Plan: This will contain all technical specifications, such as electrical schematics, mechanical drawings, material lists, and step-by-step assembly instructions. Documentation will include things like testing, assembly tolerances, and any specific equipment needed so that the production strictly follows the design.

Project Summary

After the project, the engineers provide a comprehensive outline of the whole design and manufacturing process, considering all success and failure points. Thus, they are always progressing towards other projects with betterment and improvement.

Summary and Feedback: This is the final stage of the engineers' stage, wherein design, planning, and production steps are reviewed step by step.

Final Thoughts on Transformer Design

A properly designed transformer can help in developing a sustainable power system. The approach in designing with proper selection of robust material and accuracy in all possible elements will improve its lifetime with minimal chances of malfunctions and ensure efficient operability.

With Daelim Transformer as an innovation and quality in transformer design software, you get solutions that are engineered for durability, optimized efficiency, and avoidance of downtime and costly disturbances.

Are you looking for a trusted partner in transformer solutions? Check our website or contact us at 678-548-5339 today to see how Daelim's engineering know-how can take your power systems to the next level with reliable, high-performance transformers!

Related Products

Related Article

What Is An OLTC Transformer and How Does It Work?

Are sudden voltage drops affecting your industrial operations? Your aging transformers may struggle to meet energy demands. Fortunately, Daelim's On-Load Tap Changer (OLTC) transformers offer a solution. These advanced devices allow for seamless voltage adjustments without interrupting power, ensuring stability and efficiency. Discover how OLTC transformers can enhance your energy management and protect your equipment in our comprehensive guide.

What Is An NLTC Transformer and How Does It Work?

An NLTC (No Load Tap Changer) transformer efficiently adjusts voltage levels while de-energized, ensuring stable power supply in manufacturing and industrial applications. By manually changing the transformer’s turn ratio, NLTCs maintain optimal voltage without interrupting operations. Their simplicity, reliability, and cost-effectiveness make them ideal for systems with infrequent voltage adjustments. Discover Daelim's NLTC transformers for enhanced energy efficiency.

How to Choose Transformer Supplier

Choosing the right transformer supplier is crucial for ensuring stable power supply and efficient operations. Start by identifying your specific transformer needs, researching potential suppliers, and evaluating their quality and reputation. Consider pricing, customer support, and delivery logistics. Ultimately, trust your instincts and maintain open communication to establish a strong partnership. Discover reliable solutions with Daelim for optimal energy usage.

A Guide to Tier 2 Transformers

This article discusses the EU's Tier 2 Ecodesign Regulations aimed at reducing transformer energy losses. By enhancing design and materials, these regulations lower CO2 emissions and operating costs. DAELIM Transformer is highlighted as a leader in producing compliant, high-efficiency transformers that support sustainability and improved energy performance.

How Transformer Components Function Together to Control & Deliver Electricity

This article provides an overview of the key components of transformers and how they work together. It discusses the functions of transformer windings, cores, insulating materials, and transformer oil, as well as the roles of cooling tubes, tanks, and safety features. Overall, these components ensure effective voltage regulation and safe electricity delivery.

Why Is Transformer Oil Change Important?

This article emphasizes the importance of transformer oil changes for reliable transformer operation. Transformer oil provides insulation, cooling, and protection against moisture and oxidation. Regular replacements prevent moisture accumulation, oxidation, and particle contamination, ensuring safety and efficiency. Key steps for an oil change are outlined, highlighting the benefits of routine maintenance, including enhanced reliability, extended lifespan, and reduced operational risks.